This page will illustrate the proper way to focus the laser.

What does focussing the laser actually mean?

Without going into too much needless detail, a focussed laser is one in which the laser head is a specific distance away from the material being cut, engraved or rastered, therefore the laser beam will contact the material at exactly the desired point producing the optimum effect.

When you focus the laser you just position the laser head at a specific length away from the material you are about to use.

Why focus the laser?

Because you will not achieve the desired effect you want. The damage the laser would in fact do would be irreversible and ruin your material costing you time and money. Even more alarming is that in an unfocused position the laser is far more likely to cause a fire.

When should you focus the laser?

When you focus the laser once it will stay locked in that position from that point onwards, therefore, you only need to refocus the laser when you:

- Are about to perform your first job

- Every time you change a material you are cutting.

To be clear; you would only need to focus the laser at the beginning of the job if you had multiple jobs but all using the same material for example 3mm MDF, however, if you were doing a similar multiple job but instead using a variety of materials you would need to refocus the laser when a different material to the last one was put into the laser for example your last job was on 3mm MDF and your next is on White Card.

Tip: I recommend doing all of your jobs of a certain type of material in blocks therefore, minimising the number of times you need to refocus the laser saving you time.

How to focus the laser.

You will need:

- The laser cutter must be switched on.

- You must have the metal focussing tool with you. (In model shop office)

- You must have the material you are about to cut with you.

Step 1

Lift the main lid of the laser cutter up and place the material flat onto the metal deck lining up the top left corner.

Step 2

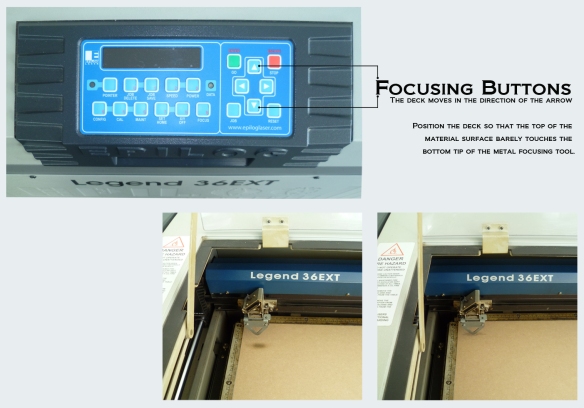

Close the lid and press the ‘focus’ button on the laser cutter machine interface.

[The laser apparatus will move from its rest position to directly above the material]

Step 3

Lift up the top window lid and place the metal focusing tool onto the laser apparatus.

Step 4

Using the up and down arrow buttons adjust the height of the laser head until the lip of the metal focusing tool barely grazes the surface of the material.

[You should still be able to move it little bit against the material surface]

Step 5

Lift the metal focusing tool up off of the laser head, close the top window flap and press the ‘reset’ button.

[The laser apparatus should move back to its original position]

The laser is now ready to execute a job onto a material of this thickness. You must now input the settings into the pc interface to control the type of job it will be.

You can refocus the laser at any point whilst it is not executing a job.